Who We Are

We offer high definition printing systems, including both Gravure Printing system and Digital Printing system. With our strong and well-built manufacturing system, certified by ISO 9001: 2015 - Quality Management System, we strive to raise the standard of high-level operating process. To offer solutions that meet all of the customers needs along with delivering quality products and services, we are ready to improve and thrive with the pace of today’s fast changing world.

What We Do

Service Solution

Consult & Suggestion

Production & QC Process

Packaging & Inventory System

Delivery

INVESTOR CORNER

SET Announcement

View AllOur Prides

2023

2021

2021

2021

2020

2019

2018

2017

2015

MEMIX

BRAND'S GEN U

Printing

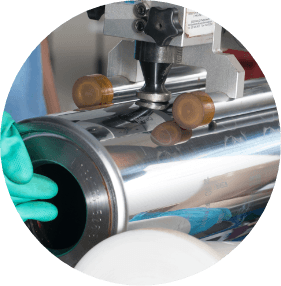

Cylinder

Digital Printing

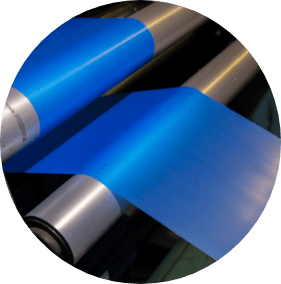

Gravure

Printing

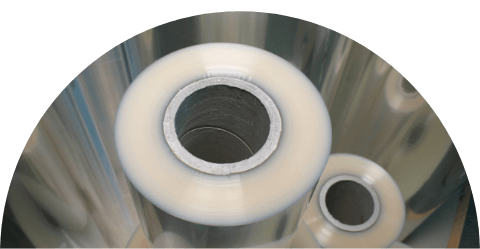

Stretch Film

Our Clients

alt="" />

alt="" />